Precision Jewelry, Watchmaking & Numismatics

Inspection of gemstones, settings, watch mechanisms, fine metalwork, and collectible coins for authentication and condition assessment.

Precision jewelry and watchmaking require visualization tools capable of revealing microscopic details. Smart G-Scope provides artisans, gemologists, and watchmakers with a versatile solution to inspect settings, soldering, mechanisms, and gemstones.

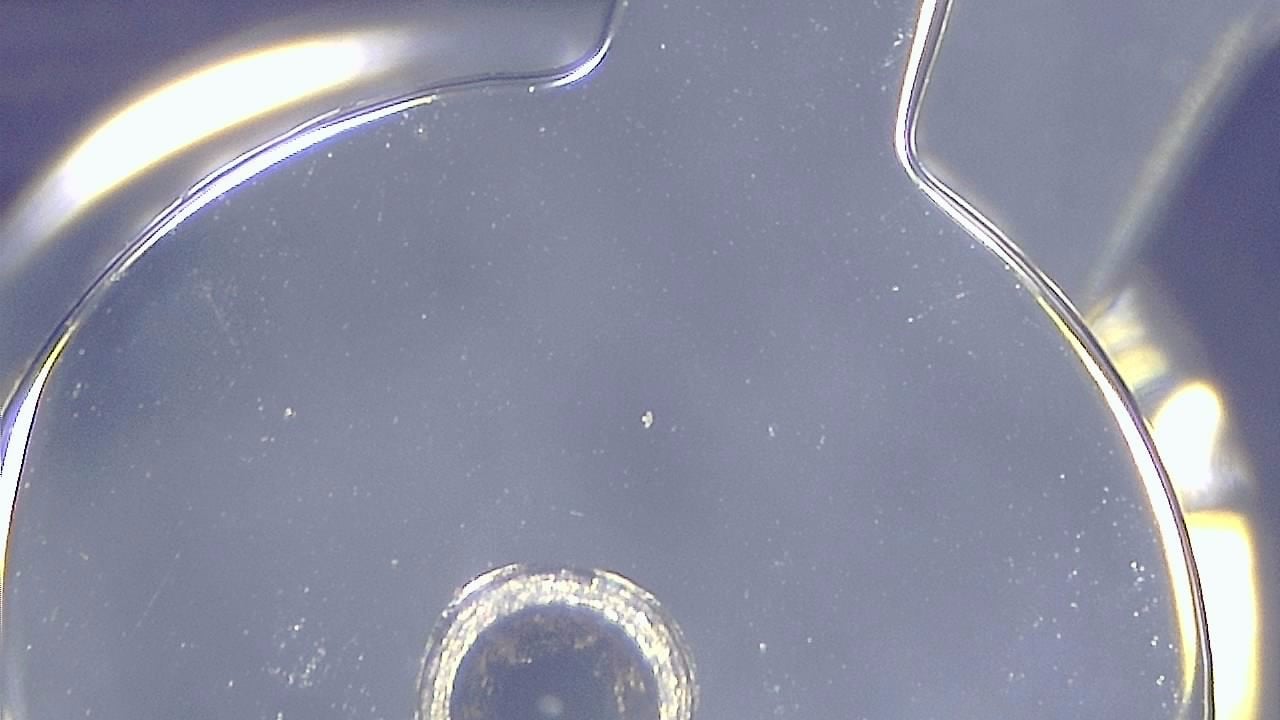

It can help evaluate gemstone quality, detect inclusions, verify setting integrity, and document restoration work with high-resolution images that can be shared with clients or insurers.

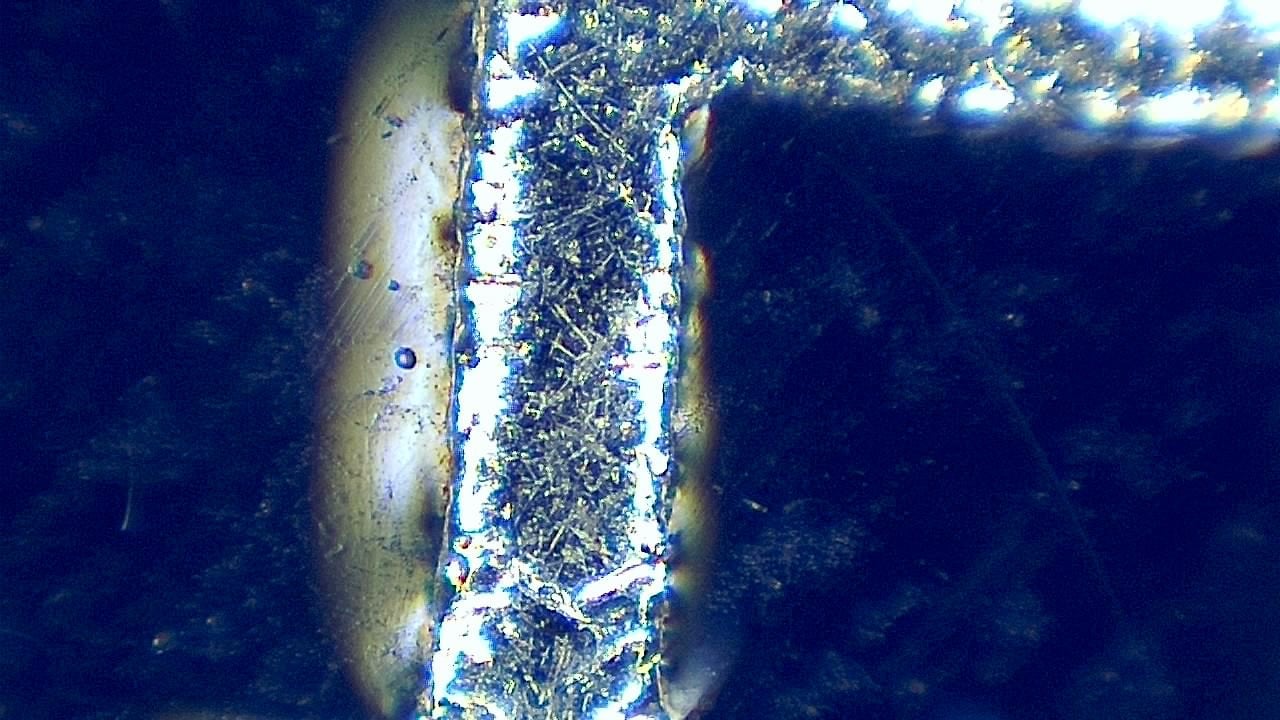

In watchmaking, it supports inspection of gears, pivots, springs, and tiny components for fault diagnosis and repair quality control.

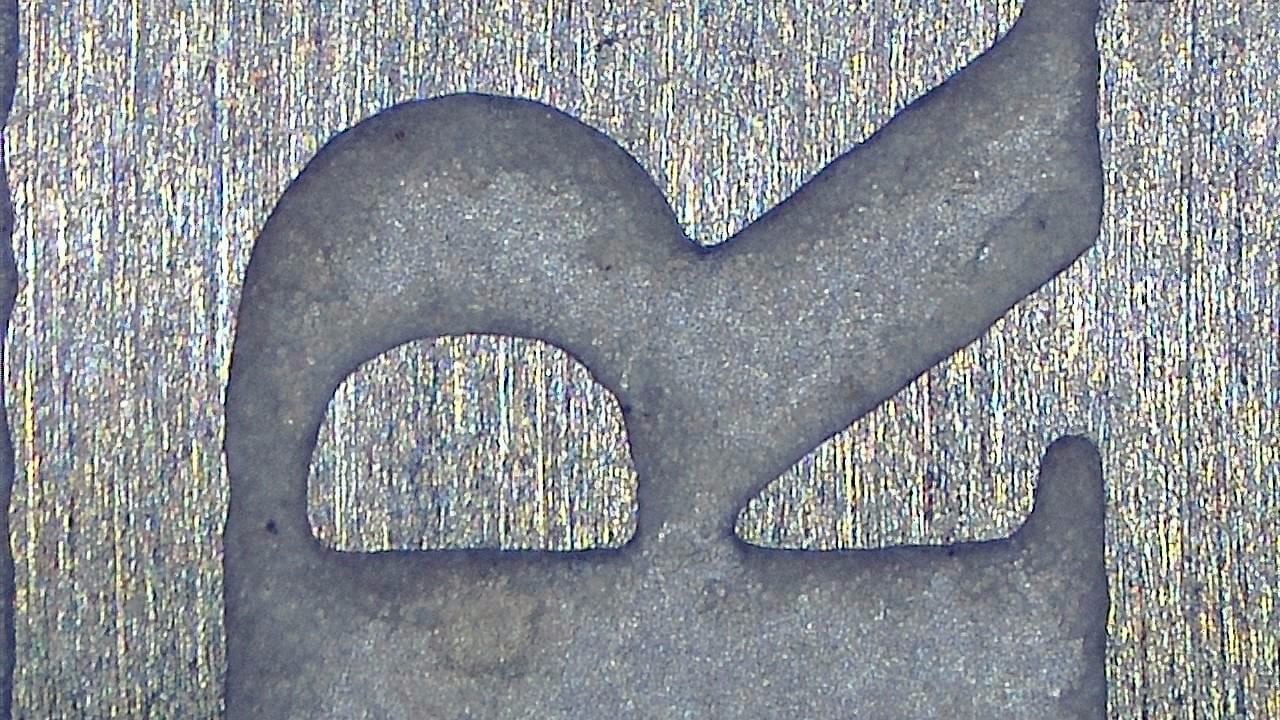

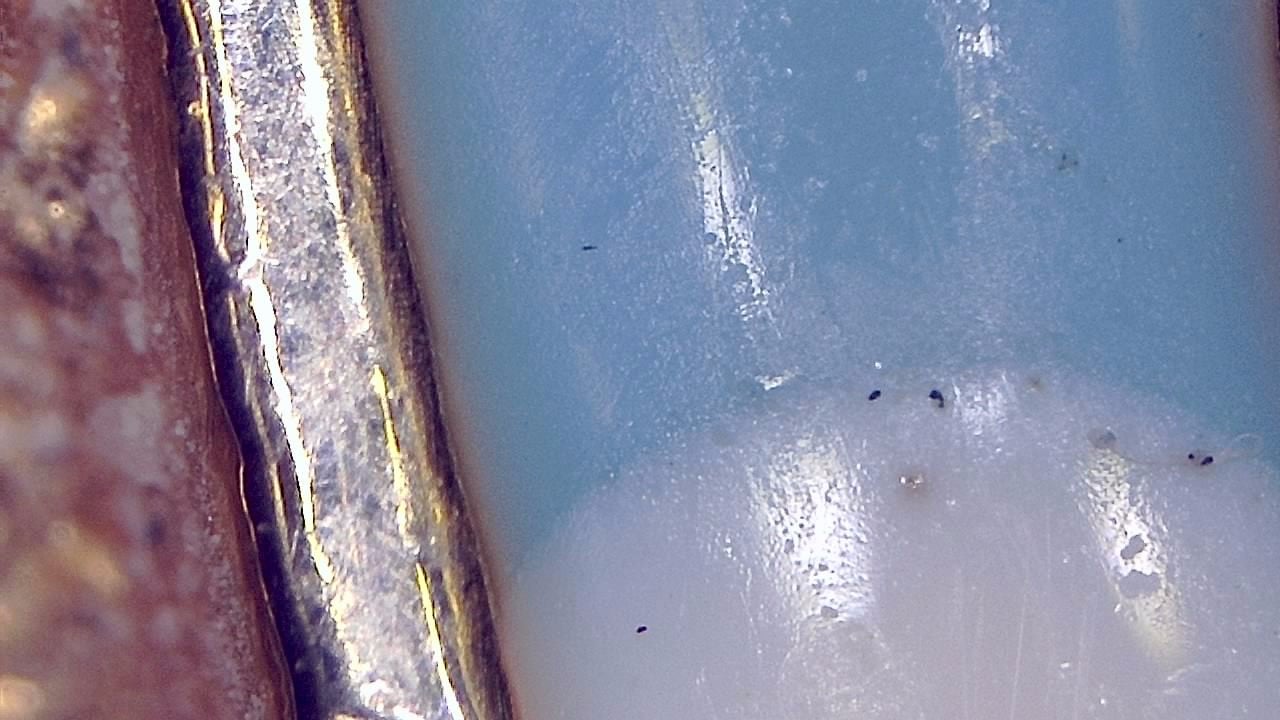

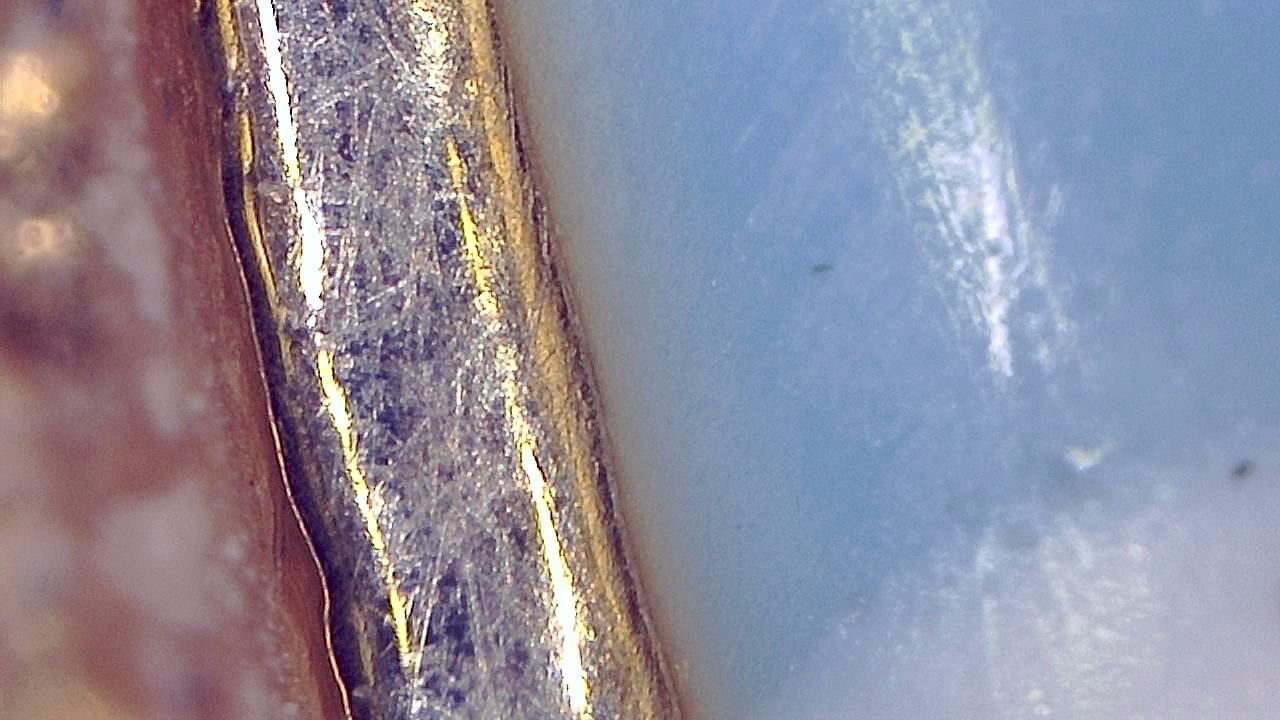

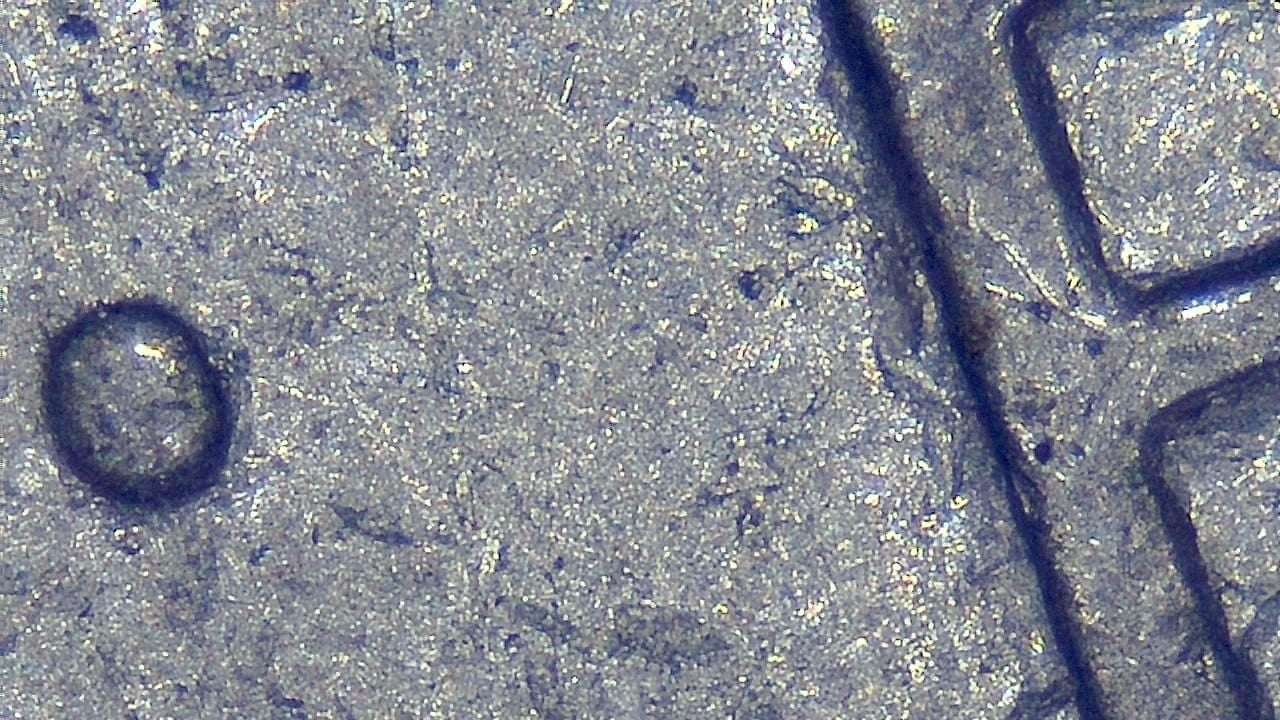

Smart G-Scope is also well suited for numismatics and collectibles: it helps examine mint marks, micro-scratches, edge details, surface texture, patina, and tool marks that can indicate cleaning, wear, or counterfeiting. High-resolution photo/video capture supports grading, sales listings, and documentation for provenance.

Key benefits

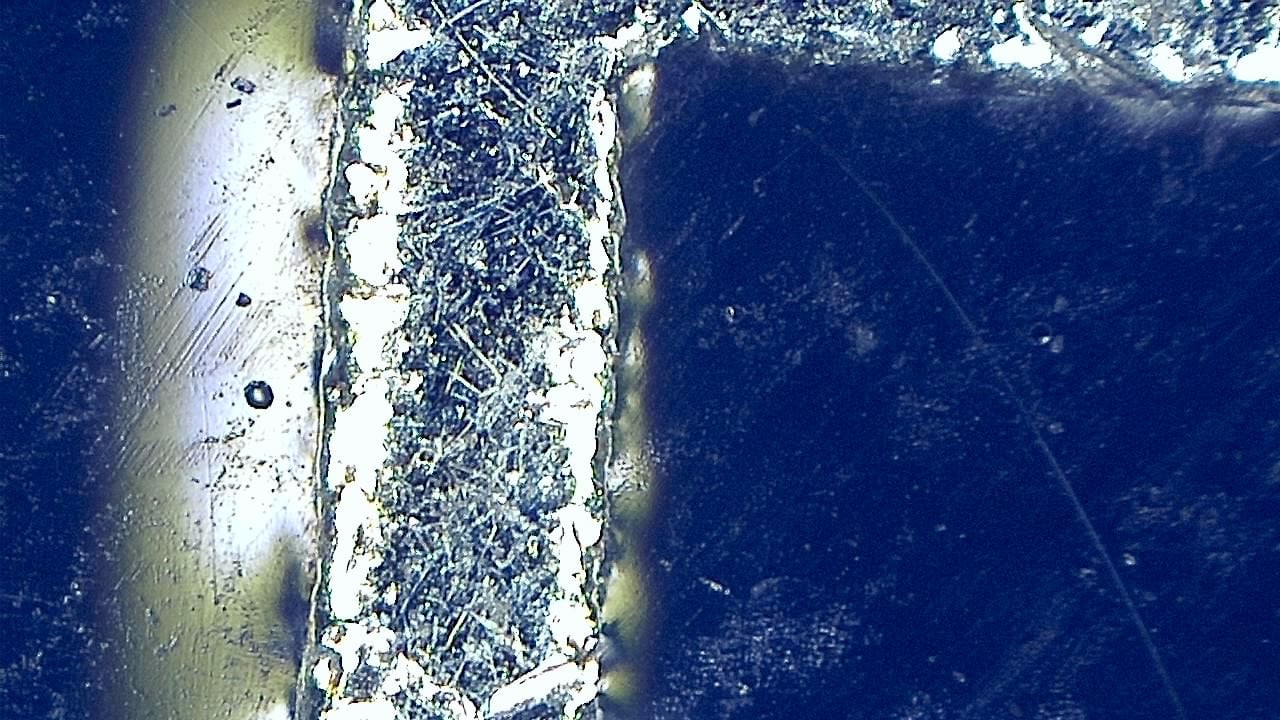

- Inspection of settings, solder joints, and finishing

- Gemstone evaluation: inclusions, fractures, treatments

- Documentation for certifications and insurance

- Diagnosis of watch mechanisms

- Authenticity checks and restoration verification

- Detailed coin inspection for grading and counterfeit detection (mint marks, micro-wear, edge features)

Practical examples

Diamond documentation for certification

A gemologist uses Smart G-Scope to document a diamond’s inclusions before issuing a certificate, capturing images that accompany the report and ensure traceability.

Vintage watch diagnosis

A watchmaker inspects the escapement of an antique pocket watch, identifying wear on escape wheel teeth that explains timekeeping drift, and documents the repair for the client.

Coin authentication and condition grading

A collector examines mint marks, edge reeding, and micro-scratches on a collectible coin to assess condition and detect suspicious tooling or surface alterations before purchase or sale.

Limitations & best practices

- For advanced gemology, complement with a refractometer and spectroscope.

- Handle parts with gloves to avoid marks and contamination.

- Adjust lighting depending on reflectance of metals and gemstones.

- Highly reflective coin surfaces or protective slabs may require angle/lighting adjustments to avoid glare and reveal texture accurately.

Interested in this use case?

Buy Smart G-Scope

Get the right kit for this application. Secure checkout and fast shipping.

Need help choosing? Tell us your workflow and we’ll recommend the best setup.

Related use cases

Electronics/PCB

Inspection of solder joints, components, and defects on printed circuit boards.

3D Printing

Surface quality control, layer defect detection, and material assessment for 3D-printed parts.

Quality Control

Fast, accurate inspection of surfaces, parts, and assemblies to catch defects before they reach the customer.

Printing

Evaluate halftones, color registration, and print defects in detail for quality control in printing and packaging.

Food

Supports visual quality control of foods and raw materials through fast inspection and documentation.

Cosmetics

Visual inspection of textures, particles, and impurities for quality control and product development.

Textiles

Detect defects in fibers, weaves, and finishes for textile quality control.